The relationship between part colour and part characteristics is much discussed on automobile forums. In this article we have tried to address the issues that arise most frequently. We hope you will find the article useful. If we haven’t answered your question, we’ll be happy to respond to you in letters and comments.

Color

Polyurethane itself is either almost colourless or has a faint pastel shade. Polyurethane is coloured by adding special pigments of various colours. Colour serves a chiefly commercial purpose for automotive parts — differentiation among manufacturers. A given manufacturer may use several colours to easily distinguish among products or batches of products made of materials with different properties.

Hardness

One of the main characteristics of polyurethanes is the wide range of hardness exhibited by manufactured products. It varies from highly elastic, soft rubbers (15 points on the Shore A scale) to rigid plastics (97 on the Shore D scale). A product’s hardness can be controlled, i.e., we can design and then produce an item with the hardness level most appropriate to the product’s purpose and application.

We mass-produce replacement parts with three levels of hardness. Each hardness level has its own colour and designation:

Hardness: 87

Hardness: 80

Hardness: 72

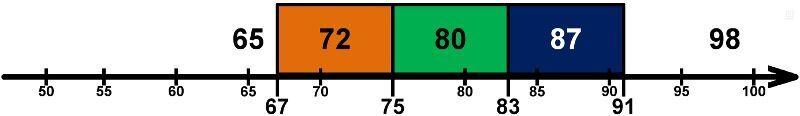

This is how we designate the three hardness levels for the material we use:

- 72 – from 67 to 75 on the Shore A scale

- 80 – from 75 to 83 on the Shore A scale

- 87 – from 83 to 91 on the Shore A scale

Choosing hardness before beginning production

We attempt to manufacture parts with a hardness comparable to that of the original in order to avoid changing the mechanical properties of the suspensions of the vehicles on which our parts will be installed. And since the rubber that parts contain usually has a hardness of from 65 to 75 on the Shore A scale, most of the silent blocks and bushings we produce have a hardness of 72 and are thus given our company’s favourite cheerful orange colour.

Some of our bushings are available in different hardness levels. The main reason for this is that our customers have repeatedly asked us to produce a more rigid version of an item. When that happens, we begin producing two versions of the part and indicate the hardness in the description, allowing the customer to choose a product with a hardness close to that of the original (orange) or a harder version (green).

In addition to colour, such parts are also differentiated by the letters R (for a hardness of 72, orange) and G (for a hardness of 80, green) at the end of the stock number.

What hardness should you select?

If you are unsure what level of hardness to choose, and especially if you have never installed polyurethane parts before, we advise beginning with the orange (softer) polyurethane. That will result in a less noticeable difference after replacing rubber parts with ones made of polyurethane, and the suspension will not seem stiffer. We are more likely to recommend choosing green-coloured bushings if you have used polyurethane previously and understand what to expect when replacing parts with more rigid versions.

In some cases, we believe only one hardness level is appropriate because of a part’s design or operating conditions and load. In these cases, we warn customers who request fabrication of bushings with a non-standard hardness level (using harder or softer polyurethane) that installing such bushings on a vehicle can have an adverse effect on a suspension, and we do not mass-produce such items.

The hardness and colour of other products manufactured by OOO «Polyurethan»

Above, we described in detail the relationship between the colour and the hardness of the parts we produce. The colour of our other products (fasteners, ice cleats, belts and other general-purpose products) serves a purely decorative purpose. Therefore, there is no specific relationship between colour and hardness, and the colour selection is much broader: orange, yellow, green, blue, brown and tan.

The colours available for every item are listed. If no colour choice is available or the item is currently unavailable in your desired colour, please leave a request and we will make it for you as soon as possible.

Conclusion

We have explained that the properties of our products are not affected by their colour, that colour only helps distinguish among them, and that colour may also help you identify the manufacturer. However, even though a given manufacturer usually employs a particular set of colours, please be aware that sometimes you will see products by different manufacturers that are coloured the same but differ in terms of quality, either by chance or on purpose. Beware of imitations and do not focus exclusively on product colour All of our products display a stock number and the address of our website, both on the packaging and on the surface of the parts.

Почему не производите межвитковые проставки( баферы)?

Анатолий, производим! Межвитковые проставки в пружины возможно подобрать и купить в нашем интернет-магазине по ссылке: https://polyurethan.ru/category/mezhvitkovye-prostavki-pruzhin-1473

Статья конечно хорошая а чем смазывать полиуретан? Какой смазкой? Подскажите…

Смазку для пыльников Шрус и установки/замены сайлентблоков возможно подобрать и купить по ссылке https://polyurethan.ru/category/smazka-1760

Хотел узнать про жесткость полиуретана и что вообще означает цвет и сразу нашел вашу статью. Спасибо за подробный ответ!

Еще больше подробностей о нашей марке новосибирского полиуретана PU54 – какие виды такой марки полиуретана бывают, с какими характеристиками, для каких целей, температур и изделий он применяется – вы можете прочитать на https://pu54.ru/

У меня вопрос:можно ли заложить в полиуретан такие с войства как скольжение. Простыми словами чтобы он скользил и не скрипел?

Евгений, сам по себе полиуретан не скрипит. Подробнее о скрипах можно посмотреть здесь: https://blog.polyurethan.ru/2019/09/12/myths/

Хочу прикупить полиуретановые сайлентблоки в рычаги на VolkswagenGolf. Нашел у новосибирского полиуретана и точки опоры. Но у знакомого на октавии стоят подобные но он не помнит какой фирмы, и в них полиуретан оторвался от обоймы. Посоветуйте какие выбрать? Спасибо

Рекомендуем в этом случае посмотреть сборные сайлентблоки. В таких сайлентблоках внутренняя металлическая втулка не приклеена к полимерному слою, она впрессовывается. Поэтому, отрыв полиуретана от металла невозможен, так как изначально отсутствует связь между металлической втулкой и полиуретаном. Прочитать про сборные сайлентблоки возможно в статье https://blog.polyurethan.ru/2013/11/21/prefabricated-polyurethane-bushings/.

сайлентблоки полиуретан какой купить лучше синий или желтый? в чем разница? спасибо за помощь!

В этом вопросе важно качество полиуретана и его характеристики. И выбор зависит от условий эксплуатации вашей техники. Полиуретан марки PU54 выпускается трех видов (в том числе морозостойкий) и в широком спектре цветов. Более подробно о свойствах и применении полиуретана PU54 возможно узнать на https://pu54.ru/

Скажите, какая разница по жесткости по сравнению с резиной если ставить полеуритан в ухо амортизатора на сотый крузак?

Доброго дня! На этих машинах довольно высокая “весовая” нагрузка на нижнее ухо амортизатора. Для TOYOTA Hilux KZN/RZN/VZN 18#, KDN215,RZN21#,VZN21#; TOYOTA Land Cruiser 100-101; TOYOTA Prado рекомендуем ставить сайлентблок арт. 1-06-2311. Этот сайлентблок 87 твердости и менее подвержен продавливанию, чем родной резиновый.

Чем отличаются сайлентблоки 2-06-4041 и 2-06-404 кроме цвета? Чем лучше или хуже запрессованная втулка сайлентблока?

Данные сайлентблоки отличаются видом конструкции. Сайлентблоки 2-06-404 имеют стандартную конфигурацию, когда внутренняя металлическая втулка приклеена к полиуретану. А сайлентблоки 2-06-4041 изготовлены по особой технологии, где внутренняя втулка впрессована в полиуретан и оторваться физически не может. Запрессованные сайлентблоки, такие как арт. 2-06-4041, показали себя в работе намного лучше. Поэтому, в приоритете производство сайлентблоков именно такой конструкции. Арт. 2-06-404 уже нет в наличии и больше его производить не планируем.

Подробнее вы можете прочитать в статье https://blog.polyurethan.ru/2013/04/15/silent-block/

Добрый день .

Подскажите – на переднею балку на Ниссан тииду латио саленблоки какого цвета лучше ставить?

День добрый! На переднюю балку у нас есть сайлентблок Артикул: 2-06-137 с твердостью 72 Шор А. На передние нижние рычаги: Артикул: 2-06-513, Артикул: 2-06-514. При покупке вы можете дополнительно проконсультироваться с нашим специалистом, сделав пометку при оформлении заказа.

Можно ли изготовить втулки реактивных тяг на классику зелёного цвета? Не нашёл на сайте!

Можем изготовить. Вы можете оформить заказ на сайте (артикулы 17-01-002 и 17-01-003). В комментарии укажите, что хотите зеленые (это будет твердость 80ед). Изготовим в течение недели после оплаты.

Здравствуйте. Слайдер цепи для мотоцикла по образцу сделать сможете?

Доброго дня! У нас есть слайдеры, выпускаемые серийно, возможно вам подойдут Слайдеры цепи. Индивидуальное изготовление зависит от конкретных особенностей ТС. Заполните пожалуйста Заявку на изготовление. Специалисты дадут подробный ответ и рассчитают стоимость.

Здравствуйте, подскажите почему нету жесткостью 90 или 100 по шор сайлентблоков для Toyota mark x grx120, grx130, lexus is-f use20, is250 gse20?

День добрый! На заказ индивидуально возможно сделать сайлентблоки и 92, и 95 единиц по ШорА Заявка на изготовление. Но с нашей точки зрения, это слишком жесткая подвеска для таких автомобилей. Вообще, на автомашинах, участвующих в трековых гонках, устанавливают подшипники вместо сайлентблоков. Если же автомобиль эксплуатируется на дорогах общего пользования, чрезмерная твердость сайлентблоков может оказать плохую услугу, так как будет возникать повышенный износ других узлов подвески (шаровых опор, амортизаторов и др.).